In the competitive PET packaging industry, even small pet preform defects can lead to huge losses from rejected batches and wasted resin to disrupted bottling lines and damaged brand reputation. Manufacturers, beverage companies, and suppliers know that maintaining preform quality isn’t optional; it’s critical for consistent performance, cost efficiency, and customer trust. At FrystalPet, we understand these challenges and help clients minimize defects through process precision, material control, and continuous quality checks.

The root of most pet preform defects lies in three areas — raw material issues, machine settings, and mold maintenance. Understanding each helps address the problem at its source rather than reacting after production.

Most of these issues are preventable with disciplined process control and regular maintenance, which is where experienced preform manufacturers stand out.

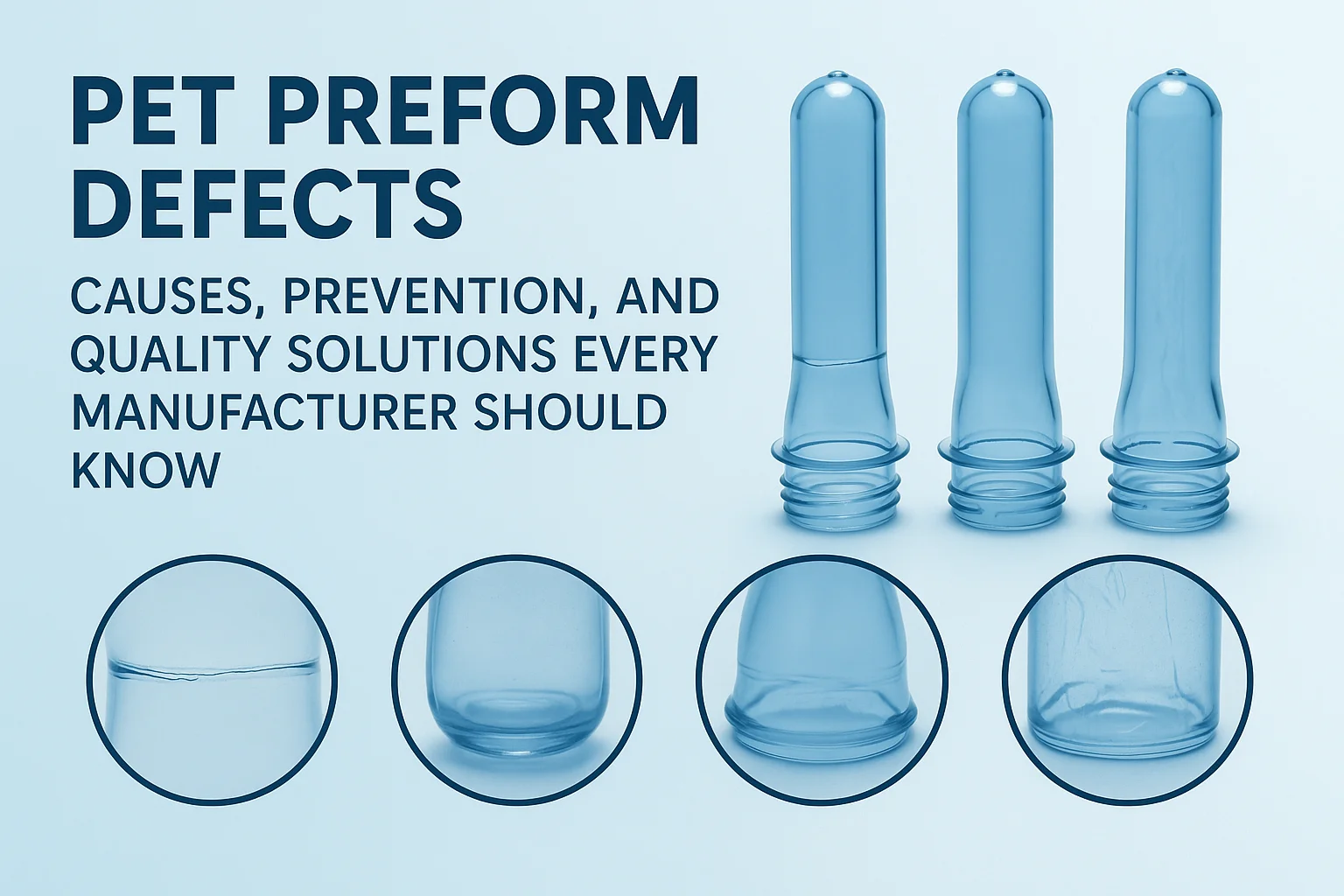

Let’s look at the most frequent pet preform defects manufacturers face and why they matter beyond just aesthetics:

| Defect | Primary Cause | Resulting Problem |

|---|---|---|

| Bubbles / Voids | Moisture or trapped air | Weak spots, leaks after blow molding |

| Black Specks | Contaminated resin or burnt material | Visual rejection, contamination risk |

| Short Shots | Insufficient filling or low pressure | Underweight preforms, bottle collapse |

| Haze or Opacity | Improper drying or temperature imbalance | Poor clarity, reduced shelf appeal |

| Flashing | Excess pressure or misaligned molds | Trim waste, increased rejection rates |

| Cracks / Stress Marks | Overcooling or sharp corners | Breakage during transport or filling |

Each of these defects affects both functionality and profitability. A single defect can trigger a chain reaction production stoppage, rework, client complaints, and shipping delays.

FrystalPet’s manufacturing line is designed to detect and prevent pet preform defects before they reach the customer. Here’s how we approach it step by step:

Addressing pet preform defects isn’t only about fixing problems; it’s about improving the overall system to prevent them from recurring. At FrystalPet, quality assurance isn’t a final checkpoint it’s a continuous process.

These measures reduce rejections, lower scrap rates, and enhance production uptime by saving both time and cost for our clients.

If you’re sourcing PET preforms for beverages, edible oils, or personal care packaging, your supplier’s ability to manage pet preform defects directly affects your brand’s performance. Before choosing a supplier, ask:

Transparent answers to these questions reflect a supplier’s commitment to quality and consistency.

For any manufacturer, eliminating pet preform defects is not just about quality assurance it’s about reliability, reputation, and reduced costs. Every bubble, speck, or crack avoided strengthens production efficiency and customer satisfaction.

At FrystalPet, we combine precision molding technology, trained teams, and strict inspection standards to deliver defect-free PET preforms trusted by beverage and packaging leaders. If you’re facing challenges with preform quality or yield loss, our experts can help you achieve consistent, high-grade output with proven technical solutions.